BY  GENN

GENN

2024/07

Blog

Are Silicone And Silicon The Same Thing?

Silicon Defined

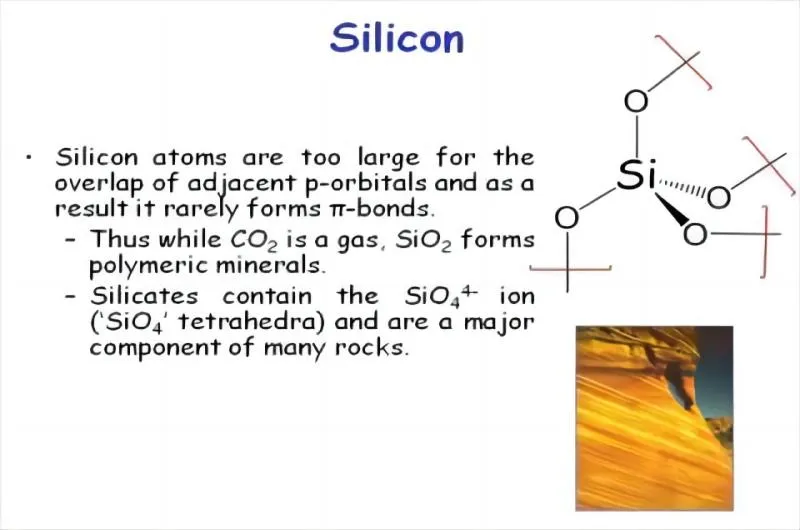

Silicon, with its atomic number 14 and chemical symbol Si, stands as a fundamental building block of the Earth’s crust. As a metalloid positioned beneath carbon in the periodic table, silicon boasts unique properties that make it indispensable in various industries.

Its crystalline structure imparts excellent semiconducting abilities, rendering it crucial for electronic applications. Moreover, silicon’s abundance in nature ensures its widespread availability for commercial use.

Exploring Silicone

Silicone is a fascinating synthetic polymer that is created from a combination of silicon, oxygen, carbon, and hydrogen atoms. Unlike its elemental counterpart, silicon, silicone is a flexible and rubber-like substance that can be molded into different forms to suit specific applications. Its molecular structure allows for customization in terms of hardness, softness, and elasticity, making it an ideal choice for a wide range of products.

Diverse Types of Silicone Compounds

Within the realm of silicone chemistry, there exist several types of silicone compounds that offer distinct characteristics and functionalities. Siloxanes are one such group of silicone compounds characterized by alternating silicon and oxygen atoms bonded to organic groups.

On the other hand, silanes are simpler silicone compounds consisting of silicon atoms bonded to organic groups like methyl or ethyl.

The Marvelous Properties of Silicone

The inherent flexibility of silicone allows it to bend and stretch without losing its shape or structural integrity – making it ideal for applications where durability and pliability are essential.

Moreover, silicone exhibits remarkable heat resistance properties, ensuring stability at high temperatures without degradation or melting. This attribute makes it perfect for use in cooking utensils, bakeware, automotive components, and electronic devices that generate heat during operation.

Additionally, silicone’s innate waterproofing ability makes it invaluable for creating seals and gaskets that prevent leaks or provide insulation against water ingress.

Key Differences Between Silicon and Silicone

- Chemical Composition: Elemental vs. Polymer

When it comes to distinguishing between silicon and silicone, a fundamental disparity lies in their chemical composition.

Silicon is a naturally occurring element with the atomic number 14, belonging to the group of metalloids on the periodic table. It is known for its semiconductor properties, making it a crucial component in the electronics industry. On the other hand, silicone is a synthetic polymer derived from silicon, oxygen, carbon, and hydrogen atoms. This distinctive molecular structure gives silicone its unique properties such as flexibility, heat resistance, and durability.

- Physical Properties: Solid Metalloid vs. Flexible Polymer

Silicon exhibits characteristics of a solid metalloid with properties such as brittleness and conductivity. It forms crystalline structures known for their stability and semiconductor capabilities essential for manufacturing electronic components like computer chips and solar panels. In contrast, silicone presents itself as a flexible polymer that can be easily molded into different shapes while retaining its elasticity. The inclusion of organic groups in silicone compounds imparts qualities like waterproofing, low toxicity, and biocompatibility, making it suitable for diverse applications ranging from kitchenware to medical implants.

- Applications: Electronics vs. Everyday Essentials

The distinct functionalities of silicon and silicone translate into specific applications within various industries.

Silicon plays a pivotal role in electronics as it serves as the primary material for semiconductors used in integrated circuits (ICs) found in smartphones, computers, and other electronic devices. Without silicon’s semiconductor properties enabling the flow of electrical currents under controlled conditions, modern technology advancements would not be possible. Conversely, silicone finds its niche in everyday essentials such as sealants for construction projects to ensure waterproofing or lubricants used in machinery maintenance to reduce friction and wear on moving parts. Moreover, silicone’s biocompatibility has paved the way for its use in medical devices like implants or prosthetics due to its inert nature within the human body.

Environmental Impact

The Footprint of Silicon Extraction

The extraction of silicon, primarily sourced from silica, quartz, and other minerals, has a notable environmental impact due to the energy-intensive processes involved. Mining operations for silicon often require significant amounts of water and energy, contributing to increased carbon emissions and depletion of natural resources.

Additionally, the byproducts of silicon extraction, such as silica dust and wastewater containing heavy metals, can pose risks to ecosystems and human health if not properly managed. The transportation of raw materials to processing facilities further adds to the environmental footprint of silicon production.

Recyclability and Sustainability in Silicone Products

Silicone products are known for their durability and longevity, which can contribute positively to their sustainability profile. Many silicone items are reusable and have a longer lifespan compared to single-use plastics or other materials.

Moreover, silicone is recyclable through specialized processes that break down the polymer into its basic components for reuse in new products. This closed-loop recycling system helps reduce waste generation and minimizes the demand for virgin raw materials like silicon.

Future Trends

The realm of silicon is witnessing an era of unprecedented growth and innovation, with emerging technologies pushing the boundaries of what was once thought possible. One such groundbreaking development is the integration of silicon photonics, where light is used to transfer data within computer systems. This cutting-edge technology holds immense promise for revolutionizing high-speed data transmission and enhancing the efficiency of communication networks. By harnessing the optical properties of silicon, researchers are opening new avenues for faster and more energy-efficient computing solutions.

In the realm of silicone-based products, a wave of transformative innovations is reshaping industries ranging from healthcare to consumer electronics. One notable advancement lies in the field of medical devices, where silicone’s biocompatibility and durability make it an ideal material for implants and prosthetics.

The development of smart silicone materials embedded with sensors promises to revolutionize healthcare monitoring by providing real-time data on vital signs and patient health metrics. Furthermore, in the realm of consumer goods, innovations such as self-healing silicone coatings are paving the way for durable and low-maintenance products that could reshape our interactions with everyday items.