BY  GENN

GENN

2024/06

Blog

Can Petroleum Coke Be Used As Coal Satisfactory?

Composition and Chemical Properties

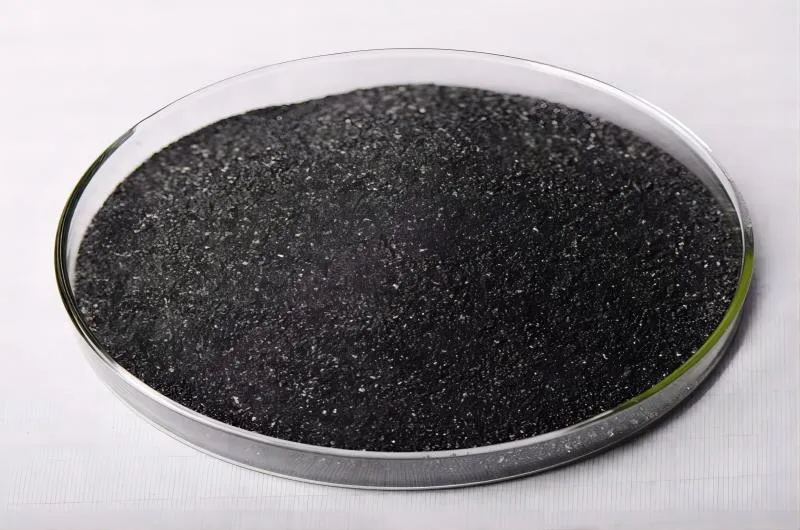

Petroleum coke, also known as petcoke, is a carbonaceous solid derived from the refining of crude oil. It is primarily composed of carbon, with small amounts of sulfur, nitrogen, and metals such as vanadium and nickel. The composition of petroleum coke can vary depending on the source of the crude oil and the refining process used.

The chemical properties of petcoke make it a high-energy fuel with a low ash content, making it desirable for use in various industrial applications. In terms of chemical properties, petroleum coke has a high carbon content ranging from 85% to 97%, which gives it a high calorific value.

It also has low volatile matter content compared to coal, meaning that it produces fewer emissions when burned. However, the presence of sulfur in petcoke can result in higher emissions of sulfur dioxide when combusted, which can have environmental implications if not properly controlled.

Energy Content Compared to Coal

When comparing the energy content of petroleum coke to coal, petcoke generally has a higher calorific value per unit mass due to its higher carbon content. This means that less petcoke is needed to produce the same amount of energy as coal.

In industrial processes where high heat input is required, such as cement production or power generation, petroleum coke can be more efficient than coal. Furthermore, pet coke’s lower moisture content compared to coal allows for more efficient combustion and less heat loss during the burning process.

This makes petroleum coke an attractive alternative fuel for industries looking to improve their energy efficiency and reduce operational costs. However, despite its higher energy content, there are concerns about the environmental impact of using petroleum coke as a substitute for coal.

Environmental Impact

One major concern is the release of greenhouse gases such as carbon dioxide and sulfur dioxide when petcoke is burned.

While petcoke has lower ash content than coal, it still emits pollutants that contribute to air pollution and climate change if not properly managed. In addition to greenhouse gas emissions, there are concerns about the disposal of petcoke ash after combustion.

The ash produced from burning petroleum coke may contain heavy metals and other contaminants that can leach into soil and water sources if not handled responsibly. Proper storage and disposal methods must be implemented to mitigate the environmental risks associated with using petroleum coke as a substitute for coal.

Advantages and Disadvantages Compared to Coal

When comparing petroleum coke to coal as a fuel source, several advantages and disadvantages come into play. One notable advantage of using petroleum coke is its higher calorific value, which translates to greater energy output per unit mass compared to traditional coal. This increased energy efficiency can result in cost savings for industries seeking more sustainable fuel options.

However, there are also disadvantages associated with using petroleum coke. One major concern is the higher sulfur content present in some grades of petroleum coke, which leads to increased emissions of sulfur dioxide when burned.

This could potentially contribute to air pollution and acid rain if not properly managed through stringent emission control measures. Additionally, handling and storage requirements for petroleum coke may differ from those of coal, posing logistical challenges for industries transitioning towards this alternative fuel source.

Environmental Concerns Related to Emissions

One of the primary challenges associated with using petroleum coke as a coal substitute is the environmental impact it can have on air quality. When burned, petroleum coke releases a variety of pollutants into the atmosphere, including sulfur dioxide, nitrogen oxides, and particulate matter. These emissions can contribute to smog formation, acid rain, and respiratory issues in nearby communities.

Additionally, the high carbon content of petroleum coke means that its combustion releases more greenhouse gases compared to burning coal. In regions where strict environmental regulations are in place to limit emissions from industrial sources, the use of petroleum coke as a fuel can pose compliance challenges for companies seeking to reduce their carbon footprint.

Efforts to mitigate these environmental concerns may involve investing in pollution control technologies or implementing alternative fuel sources that have lower emissions profiles. Furthermore, the transportation and storage of petroleum coke can also lead to environmental risks if not managed properly.

Spills or leaks during handling and transport can contaminate soil and water bodies, posing a threat to local ecosystems and human health. Proper handling procedures and infrastructure investments are essential to minimize these potential environmental impacts.

Health Risks Associated with Burning Petroleum Coke

The combustion of petroleum coke poses health risks for both workers involved in handling the material and residents living near facilities where it is burned as a fuel source. Exposure to airborne particulates released during burning can exacerbate respiratory conditions such as asthma and bronchitis. The fine particles emitted during combustion can penetrate deep into lung tissue, leading to inflammation and other pulmonary health issues.

In addition to respiratory concerns, burning petroleum coke may release toxic compounds such as heavy metals (e.g., mercury, lead) and polycyclic aromatic hydrocarbons (PAHs), which have been linked to cancer risk and other serious health effects upon prolonged exposure. Vulnerable populations such as children, elderly individuals, and individuals with pre-existing health conditions may be particularly at risk from these pollutants.

To mitigate health risks associated with burning petroleum coke as a fuel source, stringent emission controls must be implemented at industrial facilities utilizing this material. Monitoring air quality levels around plants that burn petcoke should be prioritized along with regular health assessments for workers exposed to combustion byproducts.