BY  GENN

GENN

2024/04

Blog

Ferro Silicon Zirconium: Revealing the Competitive Environment and Market Dynamics

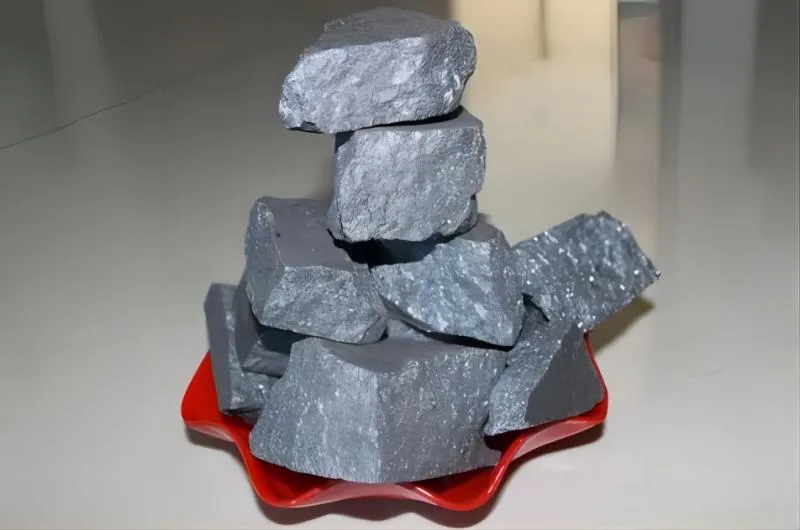

Defining the Composition of Ferro Silicon Zirconium

Ferro Silicon Zirconium is a vital ferroalloy that combines silicon and zirconium elements in its composition. Typically containing around 45–50% silicon and 3–4% zirconium, this alloy plays a crucial role in enhancing the properties of steel and other metal alloys. The addition of zirconium to silicon imparts unique characteristics to the final product, making it highly sought-after in various industrial applications.

Exploring Applications and Uses Across Industries

The versatility of Ferro Silicon Zirconium extends across multiple industries, including steelmaking, foundries, and welding. In steel production, this alloy acts as a potent deoxidizer and desulfurizing agent, improving the overall quality and performance of the steel.

Foundries leverage its ability to refine grain structure, enhance fluidity, and reduce porosity in castings. Moreover, welders often utilize ferro-silicon Zirconium as an additive to improve weldability and strength in metal joints.

Market Trends of Ferro Silicon Zirconium

Global Market Size and Growth Projections

The global market for ferro Silicon Zirconium is poised for substantial growth in the coming years. This growth can be attributed to the increasing demand for high-performance steel alloys across industries such as automotive, construction, and aerospace. The Asia-Pacific region, led by China and India, is expected to dominate the market due to rapid industrialization and infrastructure development.

Key Drivers Influencing Market Demand

Several key drivers are fueling the demand for Ferro Silicon Zirconium.

Firstly, the rising need for lightweight yet durable materials in automotive manufacturing is driving the adoption of this alloy as it enhances the strength and wear resistance of steel components. Secondly, stringent regulations on emissions control in the automotive sector are pushing manufacturers towards using high-strength steels produced with Ferro Silicon Zirconium to reduce vehicle weight without compromising safety standards. What’s more, the growing trend of sustainable construction practices is boosting demand for eco-friendly building materials like Ferro Silicon Zirconium-enhanced steel.

Emerging Trends in the Ferroalloy Industry

The ferroalloy industry is experiencing several notable trends that are shaping the future of ferro silicon zirconium. One significant trend is the increasing focus on product innovation and customization to cater to specific end-user requirements. Manufacturers are developing advanced alloy compositions with precise zirconium content to achieve the desired mechanical properties in steel products.

Another emerging trend is the integration of digital technologies such as IoT and AI in production processes to optimize efficiency and quality control. Additionally, there is a growing emphasis on sustainable practices within the industry, leading to research into eco-friendly production methods and recycling initiatives for ferroalloys.

Factors Influencing Pricing Fluctuations

The Role of Raw Material Costs

The pricing of Ferro Silicon Zirconium is significantly influenced by the costs of its raw materials, primarily silicon, zirconium, and iron. Fluctuations in the prices of these key inputs directly impact the overall production cost of ferro silicon zirconium.

For instance, any disruptions in the supply chain of silicon or zirconium due to geopolitical factors or natural disasters can lead to price spikes. Market volatility in iron ore prices also plays a crucial role in determining the final pricing of ferro silicon zirconium.

Global Economic Trends

The macroeconomic environment has a substantial impact on the pricing dynamics of ferro silicon zirconium. Economic conditions such as GDP growth rates, inflation levels, and currency fluctuations can influence demand for steel products, a major end-use sector for ferro silicon zirconium.

During periods of economic downturns, there may be a decline in demand for steel and related alloys, leading to downward pressure on prices. Conversely, during economic booms where construction and infrastructure projects are booming, there might be an uptick in demand that pushes prices higher.

Market Speculation and Investor Sentiment

Another factor influencing pricing fluctuations is market speculation and investor sentiment. The ferroalloy market is not immune to speculative activities that can artificially inflate or deflate prices.

Traders and investors closely monitor global events, trade policies, and production trends to anticipate future price movements. Sentiments like fear or optimism can create short-term price spikes or dips based on perceptions rather than fundamental supply-demand dynamics.

Supply Chain Analysis and Impact on Pricing

Complexity in Sourcing Raw Materials

The intricate nature of sourcing raw materials for ferro silicon zirconium production adds layers to its supply chain complexity. Suppliers need to secure consistent sources of silicon and zirconium ores while considering quality standards and logistical challenges associated with international trade. Any disruptions along this procurement chain can lead to delays in production schedules and impact pricing due to supply shortages.

Transportation Costs & Logistics Efficiency

Transportation costs form a critical component within the supply chain dynamics affecting the pricing of ferro silicon zirconium. The efficiency and reliability of transportation networks directly impact lead times from raw material suppliers to manufacturing facilities. Variations in fuel costs, freight rates, port congestion issues, or regulatory hurdles can all influence transportation expenses that eventually get factored into the product’s pricing structure.

Inventory Management Strategies

Effective inventory management strategies also play a significant role in determining pricing dynamics within the ferroalloy industry. Maintaining optimal inventory levels helps buffer against sudden demand surges or supply disruptions that could otherwise trigger price volatilities due to scarcity concerns. Companies adept at managing their inventories efficiently are better positioned to stabilize their pricing structures amidst fluctuating market conditions.

Comparing Ferrosilicon-Zirconium Alloys with Other Ferrous Alloys

When pitted against traditional ferrous alloys like ferrosilicon-manganese or ferrochrome, ferrosilicon-zirconium alloys offer a unique set of advantages that set them apart in terms of performance and cost-effectiveness. Ferrosilicon-zirconium blends provide improved deoxidation properties during steelmaking processes, resulting in cleaner steel with reduced impurities and gas content. This leads to enhanced mechanical properties such as increased tensile strength and ductility, making ferrosilicon-zirconium alloys preferred choices for high-strength steel applications.

In contrast to other ferrous alloys that may exhibit limitations in terms of corrosion resistance or environmental impact, ferrosilicon-zirconium alloys prove to be more environmentally friendly due to their efficient deoxidation capabilities that minimize waste generation during steel production. Additionally, the superior thermal stability of these alloys contributes to energy savings by reducing processing times and optimizing overall operational efficiency.