BY  GENN

GENN

2024/07

Blog

Is Silicone Like A Glue?

Unraveling the Mysteries of Silicone

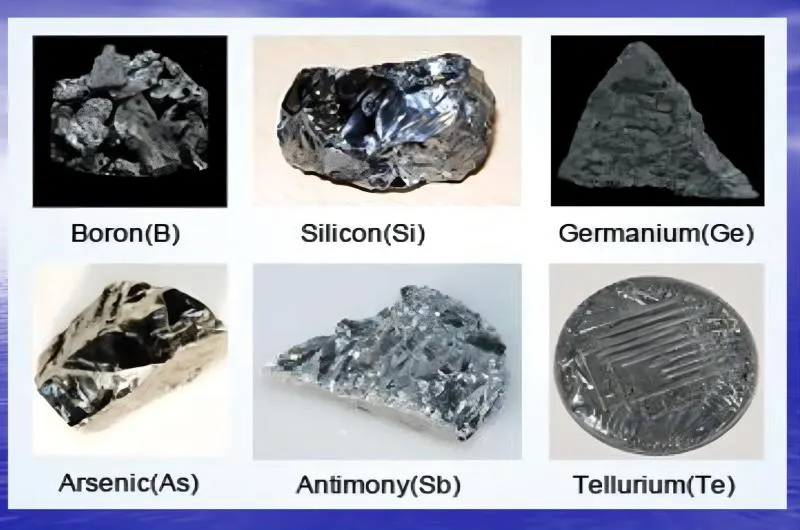

Silicone, a versatile polymer with a wide range of applications, is derived from silicon, a naturally occurring chemical element found in abundance in the Earth’s crust. The composition of silicone typically involves silicon atoms bonded to oxygen atoms, forming a robust backbone structure.

One of the most distinctive features of silicone is its remarkable flexibility, allowing it to bend and stretch without losing its shape or structural integrity. This inherent flexibility makes silicone an ideal choice for applications where movement or vibration is expected, as it can accommodate such dynamic conditions without cracking or breaking.

Furthermore, silicone exhibits exceptional durability, resisting degradation from exposure to harsh environmental factors such as UV radiation and extreme temperatures. Its ability to maintain its properties over a wide temperature range—from cold to scorching heat—makes silicone a preferred material in both industrial and consumer products.

Silicone’s outstanding temperature resistance sets it apart as a top contender in high-temperature environments where traditional glues would fail. With excellent thermal stability, silicone can withstand extremes ranging from subzero conditions to blistering heat without losing its functionality or structural integrity.

This resilience makes silicone sealants and adhesives invaluable in applications that demand longevity under thermal stress, such as automotive gaskets, electronic encapsulation, or oven seals.

Understanding Glue

Definition and Types of Glue

Cyanoacrylate, commonly known as super glue, is a fast-acting adhesive that forms strong bonds quickly. Epoxy glue is favored for its versatility and ability to bond different materials like metal, wood, and plastic with exceptional strength.

On the other hand, polyurethane glue offers excellent water resistance and is ideal for outdoor applications or projects exposed to moisture. Each type of glue possesses unique characteristics that cater to specific bonding requirements.

Properties of Glue

The ability of the adhesive to form a durable bond between surfaces determines its practicality in various applications.

Some glues set rapidly within minutes, while others require extended curing periods before reaching optimal strength. These factors influence the efficiency and reliability of the bonding process.

Applications

The applications of glue span across a vast spectrum of industries and activities. From woodworking to crafting and industrial repairs, glues play a pivotal role in joining materials together seamlessly. In woodworking projects, certain types of wood glues are preferred for their strong adhesion properties that ensure lasting bonds under stress.

Craftsmen rely on specialized adhesives to assemble intricate creations with precision and durability. Moreover, in repair scenarios where quick fixes are necessary, instant adhesives like cyanoacrylate prove invaluable due to their rapid bonding capabilities.

Adhesion Properties

Unlike most glues that rely on chemical reactions or drying processes to create a bond, silicone adhesive forms a strong bond by creating a seal between surfaces. This seal is achieved through the formation of robust molecular chains that interlock with the surfaces being bonded, providing excellent adhesion even in challenging conditions such as high temperatures or exposure to moisture.

Moreover, silicone adhesives exhibit superior resistance to UV radiation and extreme weather conditions compared to many traditional glues. This makes them ideal for outdoor applications where prolonged exposure to sunlight or fluctuating temperatures is expected.

Additionally, the flexibility of silicone allows it to absorb vibrations and movements without compromising the integrity of the bond. This flexibility contributes to its long-lasting adhesion properties, making it a preferred choice for bonding materials that may experience expansion or contraction.

Flexibility

One of the most remarkable features of silicone adhesive is its inherent flexibility, which sets it apart from traditional glues that typically harden into rigid forms upon curing. The elasticity of silicone allows it to adapt and conform to varying surface textures and contours, ensuring a secure bond even on irregular or uneven surfaces.

This flexibility also enables silicone adhesives to withstand mechanical stress and movement without cracking or losing adhesion strength over time. Furthermore, the ability of silicone adhesive to maintain its flexibility over a wide range of temperatures makes it suitable for both indoor and outdoor applications where thermal expansion and contraction may occur.

Applications of Silicone vs Glue

Common uses for silicone

As a sealant, silicone is commonly employed in construction projects to create a watertight and airtight seal around windows, doors, and plumbing fixtures. Its flexibility allows it to withstand expansion and contraction without losing its effectiveness.

In electronics manufacturing, silicone adhesives are preferred for bonding components together as they provide insulation and protection against moisture and heat. Additionally, silicone-based lubricants are used in automotive industries to reduce friction between moving parts and extend the lifespan of mechanical components.

Common uses for glue

Glues play an essential role in woodworking by bonding pieces of wood together to create sturdy furniture, cabinets, and decorative items. Woodworkers often rely on specific types of glue such as carpenter’s or wood glue for their superior bonding strength and ability to fill small gaps. In crafting, glues are indispensable for creating art projects using materials like paper, fabric, or beads.

The Lifesaving Role of Silicones in Medical Applications

Silicones play a pivotal role in the field of medical applications, particularly in the creation of prosthetics and implants. These synthetic polymers exhibit remarkable biocompatibility, making them ideal for use within the human body without causing adverse reactions. In the realm of prosthetics, silicone materials are often utilized to craft lifelike limbs or body parts that enhance the quality of life for amputees.

The flexibility and durability of silicones allow for comfortable wear while providing realistic aesthetics that mimic natural skin texture and color. Moreover, silicones are widely employed in the production of medical implants due to their inert nature and resistance to bodily fluids.

From silicone breast implants to soft tissue fillers used in cosmetic procedures, these materials have revolutionized the field of reconstructive surgery by offering safe and effective solutions for patients seeking physical enhancements or corrections. The ability of silicones to maintain structural integrity over time while seamlessly integrating with surrounding tissues has made them indispensable in various surgical interventions, leading to improved patient outcomes and increased patient satisfaction.