BY  GENN

GENN

2024/06

Blog

Is Zirconium Metal Safe?

Properties of Zirconium Metal

Physical Properties

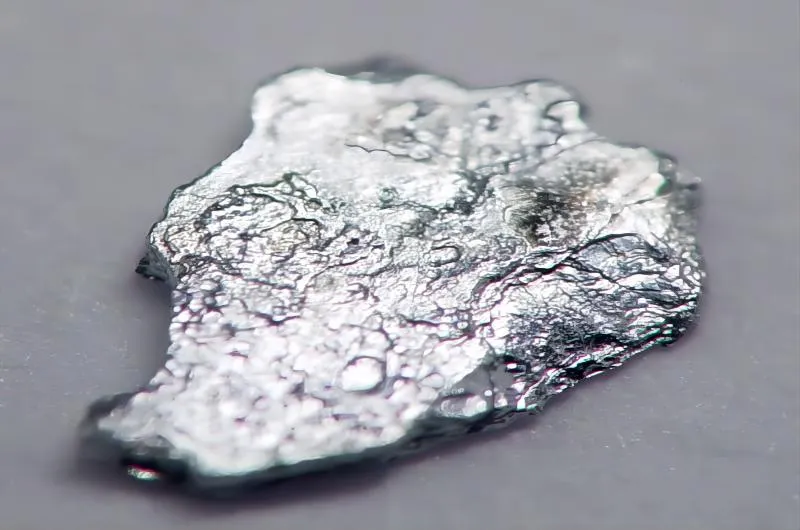

Zirconium metal, a lustrous, grayish-white transition metal, boasts remarkable physical properties that render it a valuable material in various industrial applications. One of its most notable attributes is its exceptionally high melting point, which stands at approximately 1852°C (3366°F). This exceptional heat resistance makes zirconium an ideal choice for applications that require materials to withstand extreme temperatures, such as in the aerospace and nuclear industries.

Furthermore, zirconium possesses outstanding corrosion resistance, attributed to the dense oxide layer that forms on its surface when exposed to air or water. This natural oxide layer acts as a protective barrier against corrosive elements, making zirconium highly sought-after for use in chemical processing equipment and environments where resistance to corrosion is paramount.

Additionally, zirconium exhibits a low thermal neutron absorption cross-section, meaning it has a low propensity for absorbing thermal neutrons.

Chemical Properties

When exposed to oxygen at high temperatures, zirconium forms an adherent oxide layer that provides exceptional protection against further oxidation or corrosion.

Additionally, zirconium displays reactivity with water at elevated temperatures, producing hydrogen gas through a chemical reaction known as hydrolysis.

Promoting Safety in Zirconium Metal Work

When it comes to zirconium metal processing and handling, there are several potential hazards that workers need to be mindful of. The process of refining and shaping zirconium metal can expose workers to various risks, including fire, explosion, and exposure to hazardous chemicals.

The high flammability of zirconium in powder form poses a significant fire hazard if proper precautions are not taken. Additionally, the dust generated during the grinding or machining zirconium can pose an inhalation hazard, potentially leading to respiratory issues if adequate protective measures are not in place.

To address these potential hazards, strict adherence to safety protocols is imperative. Workers involved in zirconium metal processing must receive comprehensive training on handling the material safely.

Proper ventilation systems should be installed to control the dispersion of airborne particulates and prevent the accumulation of potentially combustible dust. Personal protective equipment such as respirators, gloves, and protective clothing should be provided to mitigate the risk of exposure.

Moreover, it is essential for employers to establish clear emergency procedures and provide appropriate firefighting equipment in areas where zirconium metal is being processed or handled. By prioritizing occupational safety measures and ensuring compliance with established protocols, the risks associated with working with zirconium metal can be effectively managed.

Potential Health Effects

- Inhalation, Ingestion, and Dermal Exposure Risks

Inhalation of zirconium compounds or particles can lead to respiratory issues such as coughing, shortness of breath, and irritation of the respiratory tract.

Prolonged inhalation of high concentrations may result in lung damage or pulmonary fibrosis. Ingestion of zirconium compounds is less common but can potentially lead to gastrointestinal disturbances such as nausea, vomiting, or diarrhea. Dermal contact with zirconium-based substances may cause skin irritation or sensitization reactions.

2 . Chronic Health Implications

Chronic exposure to high levels of airborne zirconium dust has been linked to an increased risk of developing lung diseases such as chronic bronchitis and emphysema. Long-term ingestion of certain forms of zirconium compounds has been associated with potential adverse effects on kidney function.

Additionally, prolonged dermal contact with certain forms of zirconium compounds may lead to dermatitis or other skin disorders.