BY  GENN

GENN

2024/03

Blog

Market And Development Prospects Of Ferrotitanium

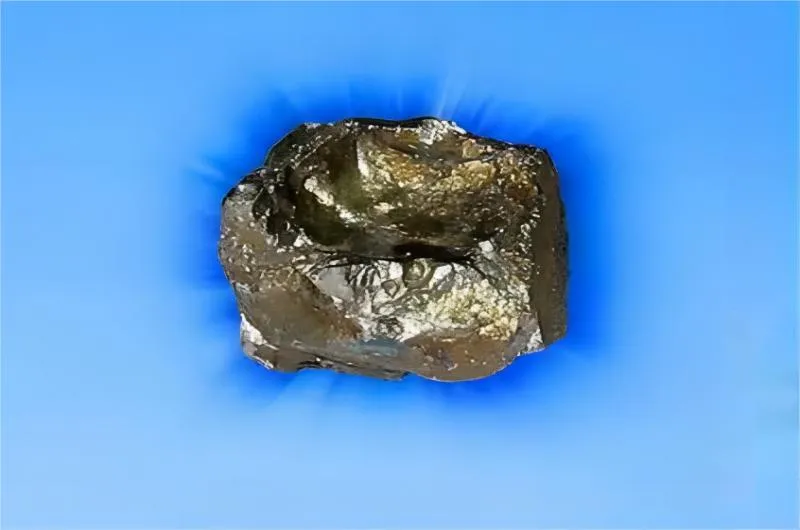

What is Ferrotitanium?

Ferrotitanium is an iron and titanium alloy with a typical titanium content of 15% to 45%. used in the steelmaking process as a steel cleaner. Titanium is important for deoxidation, desulfurization, and denitrification in the steelmaking process because of its high reactivity with sulfur, carbon, oxygen, and nitrogen. This reactivity allows titanium to produce insoluble compounds and sequester them in the slag. Steel becomes a metal with a finer grain structure when titanium is added. Ferrotitanium models include 30, 40, 70, etc.

Iron and titanium scrap can be combined to create ferrotitanium, which is then melted in an induction furnace. In order to improve the strength, hardness, and resistance to corrosion of steel and cast iron, it is also added throughout the production process. Furthermore, because ferro-titanium may enhance a product’s performance at high temperatures, it finds application in the automotive, aerospace, and construction industries.

In addition, ferrotitanium powder is well-known for its application in pyrotechnic compositions. Additionally, it is employed in the creation of alloys to boost their machining capabilities and resistance to wear. Ferro titanium is frequently used in tool and stainless steels in the steel industry, where it strengthens, boosts mechanical characteristics, and improves corrosion resistance.

Overall, because of its special qualities and reactivity with other elements, ferrotitanium is essential to the manufacturing of alloys, steel, and other industrial applications.

Titanium Industry Chain

The titanium industry chain can be classified into two types: one is the titanium dioxide industry chain; the other is the titanium material industry chain.

The titanium dioxide industry originates from the mining and selection of ilmenite and rutile, and generates titanium dioxide, a chemical intermediate product, through the sulfuric acid method and the chlorination method. The downstream is mostly utilized by the paper, plastics, and coatings sectors.

There are four primary stages in the titanium industry. Initially, the primary raw minerals utilized were ilmenite and rutile. Following enrichment and beneficiation, natural rutile and ilmenite concentrates are produced. Sponge titanium is then extracted using techniques such as magnesium reduction. Second, the primary raw ingredient is sponge titanium. To create titanium ingots, raw materials are melted and cast or intermediate alloys are added to the melted raw materials to create titanium alloy ingots; third, different specifications (shapes) of titanium products are produced by heat treatment, deformation treatment, mechanical processing of forging, rolling, extrusion, drawing, and other processes; and, lastly, deep processing processes allow titanium materials to be manufactured into parts or equipment made of titanium and titanium alloy in some industries and industrial products industries.

The Position And Role Of Titanium Industry In The Industrial Chain

As a vital link between the past and the future, the titanium industry is situated in the middle of the titanium industrial chain. Raw materials like sponge titanium make up the majority of the titanium industry upstream. The availability and price fluctuations of upstream raw materials will have a direct impact on the output and product costs of the titanium industry, as a significant number of titanium products are derived from raw material costs.

The aerospace, petrochemical, marine energy, and other industries make up the majority of the titanium industry’s downstream sectors. The market size of the downstream sector directly influences the size of the titanium industry, and shifts in the downstream industry’s demand will have a direct impact on this industry’s R&D as well as product sales. The titanium industry in my country has had additional room to grow in recent years due to the steady advancement of national policies like Industry 4.0, green development, high-end development, and modernization of the nation’s military and defense, which have all led to a gradual release of downstream market demand.

Market And Development Prospects Of Ferrotitanium

Market Size and Growth: By 2029, it is anticipated that the ferrotitanium market will have grown to a sizeable US$316.4 million. This suggests that there is a lot of room for expansion and opportunity in the sector.

Potential for Regional Development: The market research sheds light on the opportunities for regional development by highlighting growth and market space in various areas. For instance, the ferrotitanium market is anticipated to be dominated by the Asia Pacific region, primarily due to major infrastructure projects and the growth of infrastructure in developing countries such as China, India, and Indonesia.

Technological Developments and Research: The market for ferrotitanium is anticipated to expand as a result of continuous R&D efforts to enhance the alloy’s characteristics and functionality. This suggests that the sector is putting a lot of emphasis on innovation and technical developments.

Obstacles and Restrictions: Although the market offers rich prospects, obstacles like unstable raw material prices and strict laws pertaining to titanium mining and processing could impede the market’s expansion to some degree. Concerns about the environment also affect the market for ferrovanadium and ferrotitanium.