BY  GENN

GENN

2023/12

Blog

Silicon Metal Price and Market

What is Silicon Metal?

One kind of metal that is mostly made of silicon is called silicon metal. It is frequently employed in many different businesses, such as those that produce silicone goods, semiconductors, and aluminum alloys. In a high-temperature furnace, carbon is used to reduce silica, or silicon dioxide, to make silicon metal. After that, the silicon metal is purified and divided into several grades according to its composition and purity. Si331, Si441, and Si553 are a few popular grades of silicon metal; each grade has unique requirements and uses.

How is Silicon Metal Made?

Carbothermic reduction is the technique used to create metal silicon.

Raw Materials: Carbon (often in the form of coal or charcoal) and quartz (silicon dioxide) are the two primary raw materials utilized in the manufacturing of metal silicon.

Furnace Operation: Usually, an electric arc furnace is used to combine the raw components. High temperatures are reached in the furnace, typically between 2,000 and 2,500 degrees Celsius.

Carbothermic Reduction: Carbon and silicon dioxide combine inside the furnace to create silicon metal and carbon monoxide gas. The following equation can be used to illustrate the chemical reaction:

Si + 2CO = SiO2 + 2C

Depending on the intended use, the created silicon metal is then gathered and processed further into different forms, such as ingots, granules, or powders.

What Determines Metal Silicon Pricing?

1. Supply and demand: The equilibrium of supply and demand in the market influences the price of silicon metal, just like it does for any other commodity. Prices typically increase when there is a strong demand for silicon metal and a limited supply. On the other hand, prices might decrease if supply outpaces demand.

2. Production costs: The price of metallic silicon will be impacted by the costs of labor, energy, raw materials, and other production-related charges. Prices for silicon metal may rise as a result of increased production costs.

3. Market competition: Pricing will be impacted by the level of rivalry amongst silicon metal producers. In a market where there are several producers, they could attempt to draw clients by providing attractive prices. However, if there are fewer manufacturers, they could be able to set the price more freely.

4. Quality and Purity: The cost of silicon metal is also influenced by its quality and purity. Superior metallic silicon that satisfies particular industry requirements or possesses extra appealing characteristics could fetch a premium over inferior substitutes.

5. Market speculative activity: The price of silicon metal will also be impacted by the speculative actions of traders, investors, and consumers.

6. Exchange rate: The cost of silicon metal will be impacted by the exchange rate between currencies, particularly for producers and customers in other nations. The price of importing silicon metal will rise if the home currency declines, but the import program’s cost will go down if the home currency gains strength.

7. Extras: The price of silicon metal is subject to various factors, including trade policies, events in geopolitics, and general market trends.

Market Demand and Trend

Because there will be a greater need for aluminum-silicon alloys in the upcoming years, silicon metal demand is predicted to rise. These alloys are more resilient, strong, and heat-resistant due to the addition of metallic silicon, which qualifies them for use in the aerospace and automotive sectors.

Second, elements like the expansion of the electric car industry have an impact on the demand for metallic silicon. The growing popularity of electric vehicles is anticipated to drive up demand for silicon metal, which is used in battery packs and batteries.

Furthermore, semiconductors, a crucial component of electrical devices, are made from metallic silicon. The need for metallic silicon is anticipated to rise in the upcoming years because of the anticipated large growth of the global sensing market, which includes silicon-based semiconductors.

Which Countries Generate the Most Silicon Metal?

As of 2021, around two-thirds of the world’s metal silicon output came from China, making it the leading producer in the world. Brazil, Malaysia, the United States, Norway, and Russia are some of the other major producers. Hydroelectric power, in particular, is essential to the energy-intensive process of generating metal silicon, and its availability is typically linked to the production of metal silicon. Which nations are the main manufacturers of metal silicon can also be influenced by the cost and availability of the raw materials used in the process, mainly silica and carbon.

What is Metal Silicon Used For?

- Alloying agent: When making different alloys, metal silicon is frequently utilized as an alloying agent. To enhance the qualities of certain metals, including copper, steel, and aluminum, it is added. For instance, silicon is added to aluminium to improve its strength and ability to withstand corrosion.

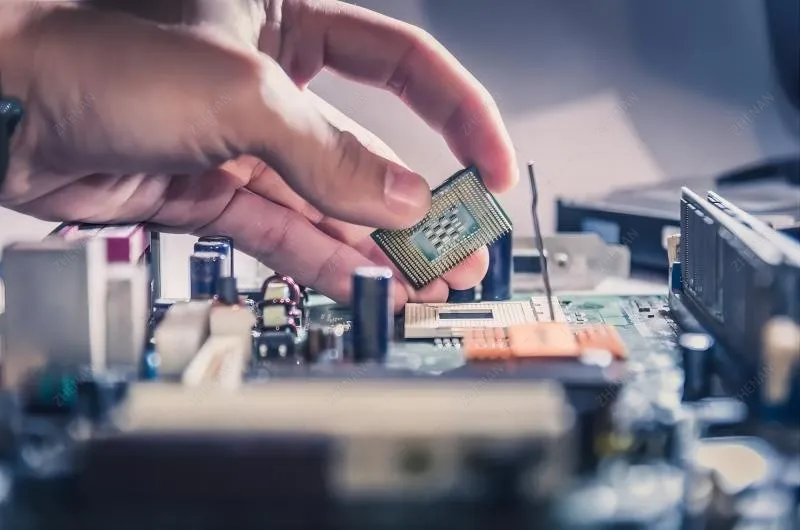

- Semiconductor industry: A key component of the semiconductor business is silicon. It is employed in the production of silicon wafers, which are the building blocks needed to create integrated circuits (ICs) and microchips. High metallic silicon purity is essential for the production of semiconductors.

- Chemical industry: To create organic silicon, the chemical industry uses metallic silicon. A class of synthetic polymers known as silicones find use as sealants, adhesives, lubricants, and electrical insulation, among other things. An essential component used in the creation of silicone is metallic silicon.

- Metallurgy: To lower the oxygen content in steel and other metals, metallurgical operations employ metallic silicon. It serves as a deoxidizer, assisting in the elimination of contaminants and raising the standard of the finished product. Additionally, silicon metal can improve the strength and heat resistance of some alloys that are used to make building materials and automobile parts.

- MEMS and Microsystems: Microelectromechanical systems (MEMS) and microsystems are made using silicon metal. Usually, it is deposited onto silicon wafers to form polysilicon structures, which are crucial parts of MEMS devices and include electrodes and conductors.

- Other applications: A wide range of other products and sectors can make use of metallic silicon. It is utilized as a raw material to produce silicon carbide and as an insulator for optical fibres and high-temperature furnaces. Furthermore, metallic silicon is employed in the manufacturing of a few metal parts, including washers, screws, and nuts.