BY  GENN

GENN

2024/03

Blog

What is the Difference Between Silicon Metal Powder and Silicon Powder?

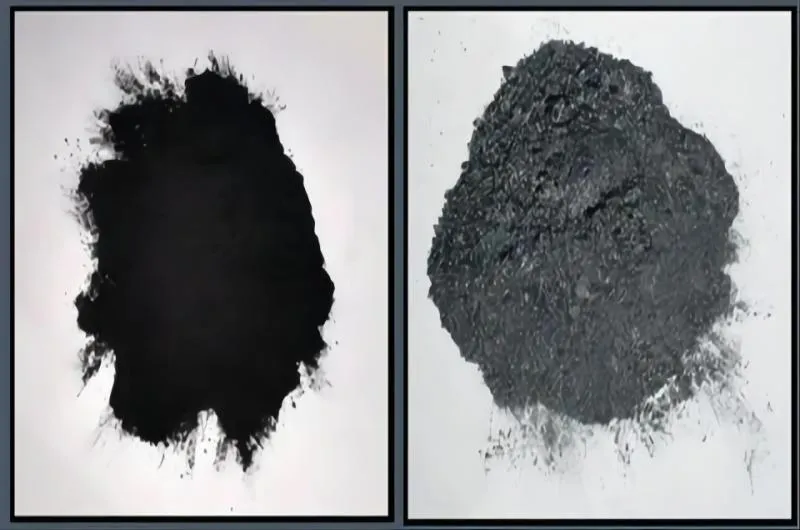

What is Silicon Metal Powder?

Metal silicon powder is a powdered silicon powder obtained by grinding metal silicon (industrial silicon). It is also called crystalline silicon or industrial silicon. Its main use is as an additive for non-iron-based alloys. It is also used as an alloying agent for silicon steel with strict requirements to smelt special steel types and deoxidizers for non-ferrous-based alloys. After a series of processes, industrial silicon can be drawn into single-crystal silicon for use in the electronics industry.

What is Silicon Metal Powder Used For?

- Metallic silicon powder is widely used in refractory materials and powder metallurgy industries and is used in steelmaking furnaces, kilns, kiln furniture, etc. to improve the high-temperature resistance, wear resistance, and oxidation resistance of products.

- In the silicone chemical industry, metallic silicon powder is the basic raw material for the synthesis of silicone polymers, such as used in the production of silicon monomers, silicone oil, and silicone rubber preservatives, thereby improving the high-temperature resistance, electrical insulation, and corrosion resistance of the product. Anti-corrosion, waterproof, and other properties.

- Metal silicon powder is drawn into single-crystal silicon, and the processed silicon wafers are widely used in high-tech fields and are essential raw materials for integrated circuits and electronic components. Electronic devices made of semiconductor silicon have the advantages of small size, lightweight, good reliability, and long life.

- In the metallurgical casting industry, metallic silicon powder is used as a non-ferrous alloy additive and silicon steel alloy agent to improve the hardenability of steel. Industrial silicon powder can also be used as a reducing agent for certain metals and new ceramic alloys. Silicon can replace aluminum in the steelmaking process, improve the efficiency of deoxidizers, purify molten steel, and improve the quality of steel.

What is Silicon Powder?

Many manufacturers require pure metals in a range of different shapes to add as additives when making products. These metals provide different properties to the products, such as hardening metals, providing corrosion resistance, or reducing oxidation. Silicon is one metal found in a wide range of industries due to its versatility and cost-effectiveness. Pure silicon powder has a fine consistency that allows it to be shaken, pressed, and bonded to other materials based on its grain size.

Silicon Powder Properties

Silicon is a chemical that has similarities to carbon and tin. It is considered extremely hard and brittle. It does not react to water, oxygen, or acids as this stability makes it ideal for a range of applications where the other base metals or applications must maintain their original characteristics in varying environments. The silicon expands when it freezes, and bonds with varying metals and other chemicals to create a uniform seal. It is also a reinforcing agent and resists corrosion and oxidation. When in powdered form, the chemical is waterproof, tolerates high temperatures well, and offers electrical insulation.

To create silicon powder, silicon lumps are broken up and milled into specific grain sizes. Some main applications for silicon powder include the following:

Adhesives & Coatings

Silicon powder has excellent bonding capabilities, making it ideal when used in sprays and coatings on varying surfaces to create a sure bond. It also prevents corrosion and oxidation due to having no reactions to water or acids.

Silicone Rubbers, Oils, and Resins

When it comes to synthetic materials, silicon powder is highly used. It is the basic metal for silicone rubbers, resins, and oils due to its water resistance, temperature tolerances, and electrical insulation properties.

Lubricants

Silicon powder offers anti-wearing and anti-aging properties. It is placed in lubricants and oils as the silicon allows the liquids to flow smoothly over metal surfaces. It forms into a film over the parts to provide enhancements to friction performance.

Semiconductors

Silicon is used in integrated circuits throughout the semiconductor industry. The powder offers thermal stability created from electrical fields and operating systems so components function without experiencing changes to their mechanical or structural properties.

Refractory Materials

Silicon offers refractory properties to processes that require the use of constant high temperatures or pressures. It may be used as a lining for iron smelting processes or mud water cannons as it resists wear, temperatures, and oxidation.

In addition to the many applications listed above, silicon powder may also be used in the manufacturing of pharmaceuticals, in food & beverage manufacturing, and in biomedical applications. The type of silicon powder that will be added to other base metals and applications is based on the grain particle size as well as the purity.