BY  GENN

GENN

2024/08

Blog

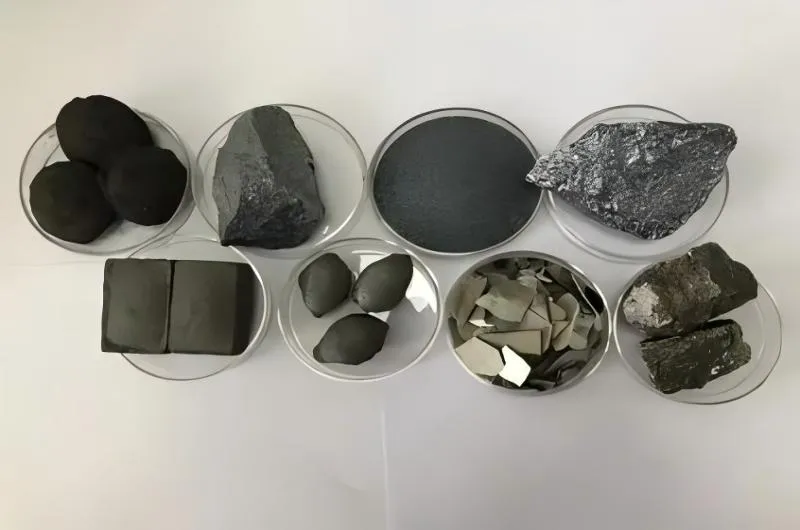

Why Do People Use Silicon Metal Powder?

Why do people use silicon metal powder? Silicon metal powder is essential in electronics for its high conductivity, a key role in semiconductors and integrated circuits, and use in silicon wafers for microelectronics.

Applications in the Electronics Industry

Silicon metal powder is necessary in the electronic devices market because of its high thermal conductivity and exceptional electrical homes. These attributes make it an essential material in the production of different electronic elements, driving the innovation of contemporary innovation.

One of the main applications of silicon metal powder remains in the manufacturing of semiconductors. These products are the backbone of electronic tools, allowing the miniaturization and efficiency improvements that have revolutionized customer electronics, computing, and telecommunications.

In addition, silicon metal powder is vital in the manufacture of integrated circuits (ICs). These circuits develop the core of mostly all electronic gadgets, from smart devices to intricate computing systems. The high pureness and high quality of silicon metal powder make certain the reputable performance and durability of these ICs.

The production of silicon wafers, which function as the substratum for ICs and other microelectronic tools, likewise counts greatly on silicon metal powder. These wafers need exact material properties to maintain the performance and functionality of the electronic components they support.

Silicon metal powder is just as vital in the creation of transistors and diodes. Transistors work as buttons and amplifiers in electronic circuits, while diodes regulate the instructions of present circulation. The usage of high-grade silicon metal powder in these elements guarantees they operate effectively and withstand the demands of modern-day digital applications.

Moreover, the duty of silicon metal powder reaches the solar power industry within the electronics market. It is made use of in the production of solar batteries, which transform sunlight into electricity. The efficiency and performance of these cells are dramatically enhanced by the premium electrical properties of silicon steel powder.

Function in the Solar Energy Sector

Silicon steel powder plays a crucial duty in the manufacturing of photovoltaic or PV cells, which are the keystone of solar power systems. These cells work by transforming sunlight directly right into electrical energy, a process known as the photovoltaic or PV effect. The distinct residential or commercial properties of silicon steel powder, especially its high conductivity and ability to soak up light successfully, make it indispensable for this application.

One of the essential reasons silicon metal powder is so crucial in the solar energy field is its semiconductor buildings. Silicon, when doped with other aspects, types p-n junctions that are vital for creating electricity from sunshine. The fine powder type of silicon steel enables specific control during the production of these cells, ensuring optimum effectiveness and efficiency.

Additionally, the usage of silicon metal powder in solar power applications is driven by its cost-effectiveness and wealth. Silicon is the second most plentiful element in the Earth’s crust, making it a lasting selection for massive production. The powder kind also assists in less complicated handling and processing, which reduces production prices and makes solar innovation much more easily accessible.

The role of silicon metal powder prolongs beyond just the photovoltaic cells themselves. It is likewise used in the production of various other parts in solar energy systems, such as photovoltaic panels and modules, where its thermal and mechanical residential or commercial properties add to the sturdiness and long life of these products. As the world continues to shift in the direction of renewable resource sources, the relevance of silicon metal powder in improving the performance and sustainability of solar energy can not be overstated.

Use in the Automotive Industry

In the automotive industry, silicon metal powder plays an essential duty in enhancing the durability and performance of numerous engine elements. Its application is crucial in the manufacturing of engine blocks, cylindrical tube heads, pistons, brake pads, and clutch plates. The residential or commercial properties of silicon steel powder, such as its high heat resistance and use resistance, are particularly advantageous for parts based on extreme temperatures and mechanical stress and anxiety.

Silicon steel powder’s payments to engine blocks and cylinder heads are notable. These elements, frequently subjected to intense warmth during operation, benefit from silicon metal powder’s capability to preserve architectural stability under high-temperature levels. The powder’s inclusion helps protect against deformation and wear, therefore prolonging the life of these crucial engine components.

When it comes to pistons, which withstand constant motion and friction, silicon steel powder enhances its resistance to deterioration. This results in improved engine performance and decreased upkeep prices. Brake pads and clutch plates likewise see significant improvements from using silicon metal powder. These components need materials that can withstand high friction and warm produced throughout stopping and equipment changing. Silicon metal powder supplies the necessary toughness and integrity.

Moreover, silicon metal powder is used in the growth of sophisticated products for the vehicle market. For example, its application in aluminum-silicon alloys boosts the performance and efficiency of lightweight engine components. These alloys use an exceptional strength-to-weight ratio, adding to the general reduction in automobile weight and boosting gas performance. Methods for

Managing Costs When Purchasing Silicon Metal Powder

Acquiring silicon steel powder can be a substantial financial investment, particularly for markets where it forms a core component of manufacturing. In browsing the complexities of its pricing, effective techniques are crucial to handle and possibly decrease expenses. This section dives into several methods tailored to enhancing expense without compromising high quality.

Working Out Long-term Contracts

Protecting long-lasting contracts with vendors can stabilize prices, potentially including terms that protect against market volatility. Such contracts can likewise cultivate stronger business connections, causing much more desirable rates or terms in the future.

Mass Purchases

Consider mass purchasing to take advantage of quantity discount rates. Providers frequently use decreased rates for bigger orders, so settling acquisition orders to satisfy bulk demands can result in significant financial savings.

Expanding Suppliers

Diversifying your supplier base can minimize dependence on a solitary vendor, enabling affordable rates and reducing risk. It’s crucial to examine the marketplace continually to guarantee you are obtaining the very best possible terms and rates.

Technological Upgrades

Purchasing innovation that can successfully utilize silicon metal powder may cause longer-term cost savings. A lot more efficient processing can minimize waste and boost yield, hence lowering the total cost each of output.

Market Timing

Understanding market patterns and timing your purchases can likewise impact costs. Prices for silicon steel powder can rise and fall based on market needs, supply levels, and exterior financial factors. Buying throughout a market trough instead of at a top can cause substantial price savings.