BY  GENN

GENN

2024/07

Blog

Why Is Silicon So Popular?

Silicon‘s Role in the Technology Industry

Silicon plays an essential function in the modern technology industry because of its phenomenal residential or commercial properties and flexibility. As the foundation of modern-day electronics, silicon is essential to the manufacturing of semiconductors, which are the building blocks of almost all electronic tools. Its unique ability to work as both a conductor and an insulator enables the specific control of electric currents, making it vital in the manufacture of transistors, the fundamental parts of silicon chips.

Furthermore, silicon’s compatibility with incorporated circuit modern technology has changed the tech industry. The development of silicon-based integrated circuits has actually allowed the creation of significantly effective and compact digital gadgets, from computers and smart devices to sophisticated medical devices and automobile systems. This has sustained rapid developments in innovation, driving development and economic growth on an international scale.

Silicon’s duty prolongs past simple microchips; it is also critical in the production of different other electronic parts such as diodes, sensors, and solar cells. These elements are important in a variety of applications, consisting of consumer electronics, commercial automation, and renewable resource systems. The integrity and efficiency of silicon-based modern technologies have actually established them as the criterion in the market.

Along with its technical advantages, the widespread accessibility and relatively inexpensive of silicon contribute dramatically to its appeal in the technology industry. Its plentiful visibility in the Earth’s crust and the effectiveness of its removal and processing make silicon a financially practical selection for manufacturers. This availability guarantees a constant supply of raw products, supporting the continuous development and manufacturing of sophisticated electronic tools.

Silicon in the Semiconductor Industry

Silicon’s unique buildings have made it the backbone of the semiconductor industry, a vital market driving technological advancement. Its semiconducting qualities enable it to carry out power under particular conditions while serving as an insulator under others, making it an ideal product for making integrated circuits and transistors.

In the manufacture of semiconductors, silicon is commonly utilized in its highly purified form, referred to as monocrystalline silicon. This purity is important, as even minute impurities can significantly influence the performance of semiconductor gadgets.

Silicon’s extensive schedule and relatively affordable likewise contribute to its supremacy in the semiconductor sector. Contrasted to various other possible products, silicon is plentiful and simpler to collaborate with on a huge scale, making it an economical option for mass production. Additionally, the well-established framework and substantial understanding base around silicon-based innovation further strengthen its condition as the recommended material in semiconductor manufacturing.

Moreover, silicon’s compatibility with existing semiconductor manufacturing processes is a considerable advantage. For many years, considerable financial investments have actually been made in establishing silicon-based innovation and construction centers. This has led to a mature and optimized ecosystem that sustains the reliable manufacturing of silicon semiconductors, reducing costs and enhancing dependability.

Future Prospects of Silicon in Emerging Technologies

As we look in the direction of the future, the relevance of silicon in emerging innovations remains undeniable. Silicon’s unique residential properties remain to position it as a cornerstone in the advancement of next-generation advancements. Among one of the most promising locations is the field of quantum computing. Silicon-based quantum CPUs are acquiring a grip because of their prospective to take advantage of existing semiconductor construction techniques, making them a cost-effective and scalable solution for quantum computer developments.

One more exciting frontier remains in the world of expert systems (AI). The assimilation of silicon in AI hardware, specifically in neuromorphic computers, intends to imitate the neural architecture of the human mind, making it possible for much more effective and powerful AI systems. This approach could change how we procedure and evaluate large quantities of data, causing considerable breakthroughs in various markets.

In the power sector, silicon’s role in the advancement of next-generation solar batteries and energy storage space services can not be overemphasized. Innovations such as perovskite-silicon tandem cells promise greater efficiency rates, while silicon-based anodes in lithium-ion batteries are anticipated to enhance power density and battery life.

Furthermore, the ongoing research in versatile and wearable electronic devices is opening up brand-new possibilities for silicon. The development of silicon nanomaterials and stretchable silicon-based circuits is leading the way for a new class of electronic gadgets that are not only more versatile but also a lot more incorporated into our day-to-day lives.

How does silicon contribute to the renewable energy sector?

Silicon‘s Role in the Renewable Energy Industry

In the field of renewable energy, silicon is essential, especially in the manufacturing of solar and wind turbines. The adaptability and uses of this material enhance the environmental effect, durability, and efficiency of renewable energy sources.

Silicon’s Role in the Renewable Energy Industry

In the field of renewable energy, silicon is essential, especially in the manufacturing of solar and wind turbines. The adaptability and uses of this material enhance the environmental effect, durability, and efficiency of renewable energy sources.

- Solar Panels:

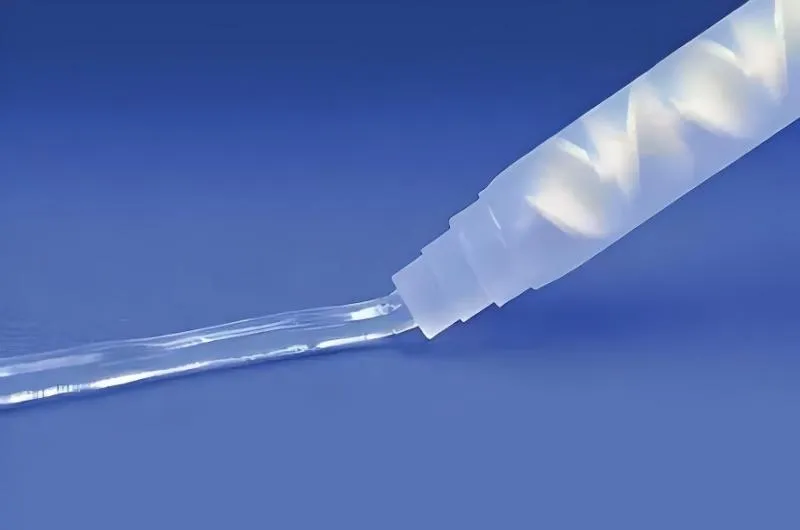

Conductive Adhesives and Encapsulants: Silicones are used as conductive adhesives and encapsulants in the manufacturing of solar panels. They provide durable bonds, seals, and electrical insulation, contributing to the reliable interconnection of solar cells and supporting high electrical conductivity and flexibility. This enhances panel efficiency, reduces repair costs, and ensures a longer panel lifespan.

- Mechanical and Chemical Properties

Silicones’ resistance to UV radiation and temperature changes, as well as their superior transparency, improve panel efficiency and reduce repair costs, contributing to cost reductions in the solar sector.

Custom Silicone Materials: Custom silicone materials, such as kSilVAC, are designed to aid in the construction of solar panels, increasing the speed and environmental efficiency of renewable energy production.

- Wind Turbines

Bonding Agents and Lubricants: Silicones are used as bonding agents and lubricants in the manufacturing of wind turbines, increasing the durability and weather resistance of rotor blades. This facilitates the construction of larger wind turbines, leading to greater energy production.