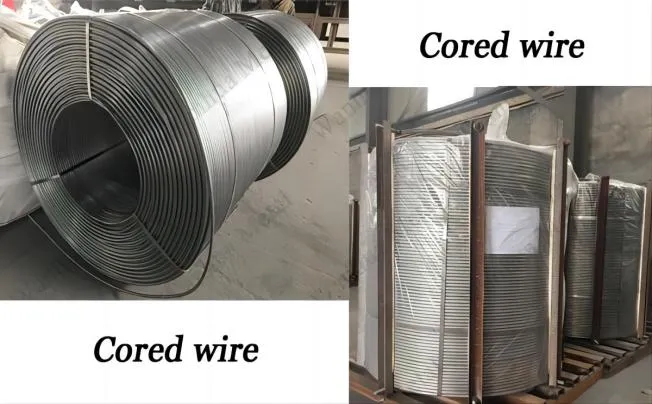

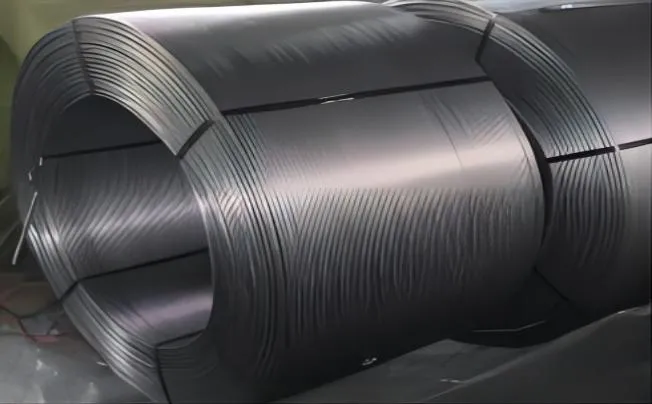

What is the Cored Wire?

The purpose of the cored wire is to crush different additives (deoxidizer, desulfurizer, modifier, alloy, etc.) into a certain particle size to be added to the molten iron or steel. Cold-rolled low-carbon steel strips are then used to integrate the additives into one body with any length of composite material.

What is CaFe Cored Wire?

Product name: CaFe

Type: cored wires with Calcium and iron powder mixture

Melting point: 839℃ (1558°F)

Boiling point: 1484℃ (2703°F)

Iron powder makes up the remaining 25–35% of calcium particles in CaFe-cored wire. The steel strip is used to make the core wire. The calcium 30 and calcium 40 cored wire parameters are their general characteristics. Calcium iron-cored wire is typically utilized in low-carbon, ultra-low-carbon, low-silicon, and pure steel that must meet stringent domestic and international inclusion morphology and quantity standards.

In addition to lowering nozzle clogging, it can prevent sulfide inclusions in steel following the addition of calcium, enhancing the anisotropy of the steel when used as a deoxidizer in the refining of molten steel. The molten steel can be heated and dissolved in a deep pool of molten steel with the aid of a wire feeder, which will remove impurities and deoxidize and desulfurize it. In the interim, it can stabilize the mixture, adjust the composition, and increase the yield of metal and rare earth elements. Lower the cost of refining and lower the quantity of valuable materials.

It works well for treating molten steel with calcium during the secondary refining process. For medium and small EAF, Φ 13mm is appropriate, and for large EAF, Φ 16mm is appropriate.

| TYPICAL FILLING RATE | ||

| Wire Diameter | 9 mm | 13.6 mm |

| Powder Metric Weight (g/m) | 115 | 275 |

A particular kind of cored wire called calcium-iron cored wire has a specified amount of iron powder and metallic calcium powder wrapped around it. Currently, CaFe cored wire is used by both domestic and international steel firms to refine steel. This process calls for low-carbon, ultra-low-carbon, and low-silicon steel, and it has stringent guidelines on the type and amount of inclusions.

Zhen’an Metallurgy is a proficient provider of cored wire, possessing various manufacturing lines for cored wire. Customized cored wires are acceptable, and we’ll accommodate client requests in a variety of methods based on equality and mutual gain.

What Are the Main Features of CaFe Cored Wire?

- The technical performance is good and able to fulfill high-speed feeding needs.

★ After treatment, the silicon, hydrogen, and nitrogen content of molten steel does not rise, making it suitable for use as a deoxidizer, desulfurizer, and de-inclusion agent.

- Enhances the rate of element recovery from alloying, with calcium recovering at a rate of 12%–19%.

- It is possible to consistently regulate the amount of Al and S in steel, enhance its mechanical qualities, and noticeably increase its plasticity, transverse impact toughness, and hot workability.

What Precise Function Does Cored Wire Serve in Casting and Steelmaking?

In the process of casting and producing steel, cored wire is essential. It is a product with very high economic benefits due to its extremely good utilization rate, energy saving, and environmental protection, thus it can dissolve and absorb alloy powder better.

Which kinds of cored wire are available?

There are numerous varieties of cored wires, including carbon wires, silicon-barium-calcium cored wires, calcium-silicon cored wires, spheroidized wires, inoculant wires, and silicon-aluminum-barium-calcium cored wires. Essentially, any type of alloy can be rolled into a wire with a core for use.

What are the applications of CaFe cored wire?

-

Steel production: CaFe-cored wire is used in the production of low-silicon steel. It serves as a deoxidizer and helps improve the quality of the steel produced.

-

Metallurgical performance: CaFe-cored wire has superior metallurgical performance compared to conventional CaSi (Calcium Silicon) and CaFeAl (Calcium Iron Aluminum)-cored wires. Its use can lead to a strong reduction in impurities and improve the overall quality of the steel.

-

Automotive manufacturing: Metal-cored wire, including CaFe-cored wire, is commonly used in robotic welding applications, particularly in automotive manufacturing. Its ability to carry higher current densities allows for faster travel speeds during the welding process, making it a preferred choice for efficient and high-quality welds.

-

Galvanized steel welding: CaFe-cored wire formulated specifically for galvanized steel can address the challenges associated with welding this material. It enables faster travel speeds and helps maintain a balance in the time/temperature relationship during the welding process. This type of wire is often used in applications where solid wire would require slower welding speeds and higher heat input.