What is Cored Wire?

Metal-cored wire was first introduced in 1973. It is a hollow metal tube that is filled with a mixture of chemical, mineral, and metal powders. Iron makes up the majority of the powder core, with different quantities of additional components added to achieve certain results, such as lower oxidation or stronger impact strengths. To obtain different weld quality, additional elements are also added, although the manufacturers of filler metal keep the combinations confidential.

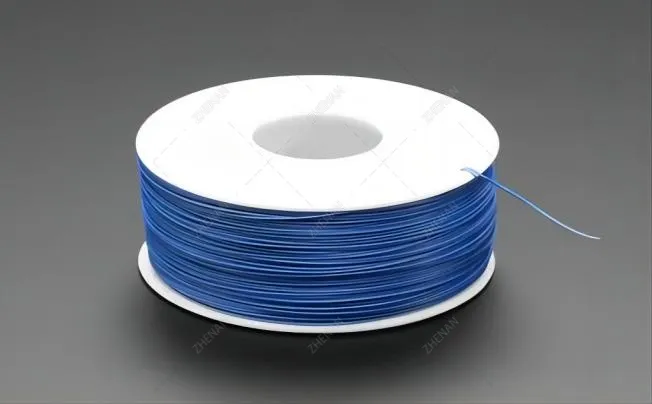

The metal-cored wire is appropriate for almost all kinds of steel, including mild, low-alloy, and stainless steel. It comes in diameters ranging from 0.035 inches to 3/32 in. On the other hand, welding sheet metal is not advised.

Properties of Cored Wire?

- It is advantageous for accurately managing ingredients, lowering smelting costs, shortening smelting times, and significantly increasing alloy yield by changing and controlling the concentration of easily oxidized components and trace elements.

- It may enhance the quality of molten steel and enhance the casting condition. It can also purify molten steel and somewhat alter the kind and shape of slag inclusions.

- Cored wires come in two varieties: externally drawn and internally drawn. The mechanical apparatus used for wire feeding is compact, dependable, and easy to operate. Specifically, the internally drawn cored wire is more suited for confined areas.

Classification of Cored Wire

The welding material known as flux-cored wire is made up of a metal sheath that is loaded with metal powder or flux. It provides filler material and enhances the quality of the weld in a variety of welding methods. Cored wire classifications might change based on the industry and particular use.

- AWS categorization: For flux-cored wires used in arc welding, the American Welding Society (AWS) offers a categorization system. The location of the welding, the shielding gas, and the type of flux are used to categorize. For instance, AWS guidelines can be used to categorize stainless steel flux-cored arc welding.

- Base Metal Classification: The base metal that flux-cored wires are intended to be welded with can also be used to categorize them. For instance, flux-cored wires are made expressly to be used in the welding of metals such as aluminum, carbon steel, and stainless steel.

- Application Classification: Based on the intended uses, core-clad wires can be categorized. For flame welding, brazing, and soldering, for instance, there are flux-cored wires available.

- It is important to remember that the industry and particular standards adhered to can affect how cored wire is classified. For precise classification information, it is therefore always advised to consult the applicable industry standards or product specifications.

What is the Use of Cored Wire?

- Better deposition rates: Metal wires can offer better deposition rates than solid wires, which enables faster welding speeds and more productivity.

- Boost welding quality: Flux or alloy elements can be found in the core material of metal welding wire, which aids in boosting welding quality. For instance, using metal for welding promotes cleaner welds and offers superior protection against airborne contaminants.

- Enhanced Penetration: When welding thicker materials or applications that call for strong weld penetration, metal welding wires can be made to penetrate further into the base metal.

- Versatility: Metal welding wire is suitable for all-position welding as well as other welding situations. This enables more versatility in welding processes and makes it appropriate for a broad variety of applications.

- Less spatter: When welding, some metal wire types—like metal flux-cored wire—create less spatter than solid wire. This increases overall welding efficiency and lessens the need for post-weld cleanup.

What is the Difference Between Solid Wire and Metal Cored Wire?

- Composition: Solid wire is formed from a uniformly sized solid metal core, typically consisting of copper or aluminum. In contrast, metal core wire consists of a hollow core encased in a metal sheath and filled with metal powder or alloy.

- Deposition rate: Compared to solid wire, metal-cored wire often has a higher deposition rate. This translates to quicker welding speeds since it can deposit more welded metal in a given amount of time.

- Penetration: Compared to solid wire, metal-cored wire usually has a lower penetration depth. This can be useful when it comes to welding thin materials or essential heat input management.

- Spatter: Compared to solid wire, metal-cored wire creates less spatter while welding. This increases overall welding efficiency and lessens the need for post-weld cleanup.

- Welding position: Metal flux-cored wire is typically favored for all-position welding, including vertical and overhead welding positions, whereas solid welding wire is typically used for flat and horizontal welding positions.

- Shielding gas: An external shielding gas, such as argon or a combination of argon and carbon dioxide, is frequently needed for solid wire welding. A greater variety of shielding gases, including mixes with a higher carbon dioxide content, can be employed with metal cored wire.

Manufacturing Process of Cored Wire

- Material selection: The initial stage of producing cored wire involves choosing the right material, which includes the metal needed for the sheath and the metal powder or flux that will be inserted inside.

- Sheath production: Continuous metal strips are typically used to create metal sheaths. A machine shapes the strip into a tubular shape by feeding it through it. The edges of the strip are then sealed or welded together to create a continuous sheath.

- Filling with flux or metal powder: The necessary flux or metal powder will be added once the sheath has been produced. Numerous techniques, including extrusion, pressure filling, and gravity feeding, can be used to accomplish this.

- Sealing: To stop flux or metal powder from leaking out of the sheath once it has been filled, seal the end. This can be accomplished by welding, crimping, or applying specialist sealing methods.

- Cutting and cooling: To harden the flux or metal powder within, cool the filled and sealed flux-cored wire. The wire is cut into the appropriate lengths for distribution and packaging after cooling.