What is Electrolytic Manganese Flake?

The metallic element manganese, Mn, can be found in pure form as electrolytic manganese. Mn concentration ranges from 99.7% to 99.9%. It is called “electrolytic” because electrolysis is used in the refining process. In other words, an electric current-driven chemical reaction.

One type of manganese metal that is created via an electrolytic technique is called electrolytic manganese flake. It is extensively utilised in the manufacturing of alloys other than steel, including stainless steel and steel. An essential part of the desulfurization, deoxidation, and alloying processes is electrolytic manganese flake. Steel’s resistance to corrosion, abrasion, and tenacity can all be increased by it.

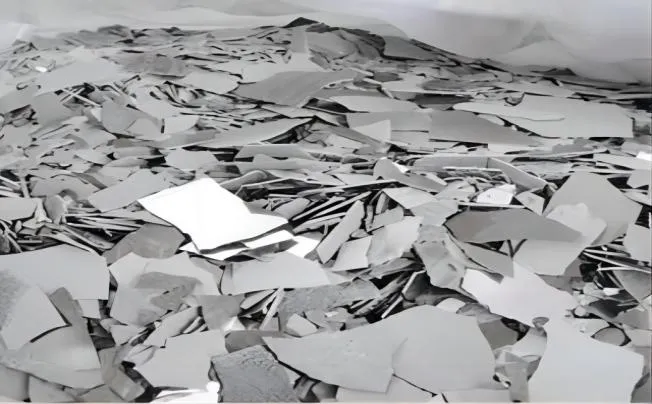

Electrolytic manganese flakes have a rough, brown surface on one side and a bright, silvery-white, uneven form resembling iron. Their texture is hard and brittle, and their colour varies from brown to silvery-white. Electrolytic manganese flakes will turn silvery grey when ground into a powder.

Electrolytic manganese flakes are well-known for their applications in adding manganese to alloys that need it and for alloying with steel. Additionally, they can be alloyed to create highly ferromagnetic materials with copper, antimony, aluminium, or other metals. With a manganese percentage ranging from 99.7% to 99.9%, electrolytic manganese is usually exceptionally pure.

Manufacturing Process of Electrolytic Manganese Flake

Electrolytic manganese flake is made by a multi-step process.

Manganese carbonate ore powder is the raw material used in the production of electrolytic manganese flake.

Leaching: A manganese sulphate solution is created when sulfuric acid is used to leach the source material.

Electrolysis: The electrolytic metal manganese sheet product is made by the electrolytic process. An electrolytic cell’s cathode is filled with the manganese sulphate solution. Manganese is deposited in layers on a stainless steel cathode sheet using electric current flow.

Flake Formation: The manganese that has been deposited takes the shape of erratic flakes that resemble iron. The flakes have a sparkling, dazzling side and a rough, uneven side. The flakes might be brown or silver-white.

Flake Processing: If necessary, the flakes can be processed one more time to create a powder. Electrolytic manganese has a silver-grey appearance when it is powdered.

Electrolytic manganese flake’s manganese content ranges from 99.7% to 99.9%, and its purity might vary, but it is usually very high.

What are Electrolytic Manganese Flakes Used For?

There are several uses for electrolytic manganese flakes; however, they are mostly found in the steel and alloy manufacturing industries. Here are a few typical applications:

- Steelmaking: As an alloying agent, steel is mixed with electrolytic manganese flakes. They strengthen, harden, and make steel more resistant to corrosion. Manganese has a special ability to improve the qualities of stainless steel.

- Alloy Production: Non-steel alloys are made using electrolytic manganese flakes. To enhance the ferromagnetic qualities and other desired features of alloys made of metals like copper, aluminium, and other metals, they are added.

- Desulfurization and deoxidation: In the steelmaking process, electrolytic manganese flakes are essential for desulfurization and deoxidation. Higher-quality steel products are produced as a result of their assistance in purging molten steel of impurities like sulphur and oxygen.

- Chemical Industry: The chemical industry uses electrolytic manganese flakes. They are employed in the manufacturing of numerous compounds, such as pigments, fertilisers, and batteries.

- Environmental Protection: Applications involving electrolytic manganese flakes are used to protect the environment. They are employed in the removal of heavy metals and other impurities from wastewater.