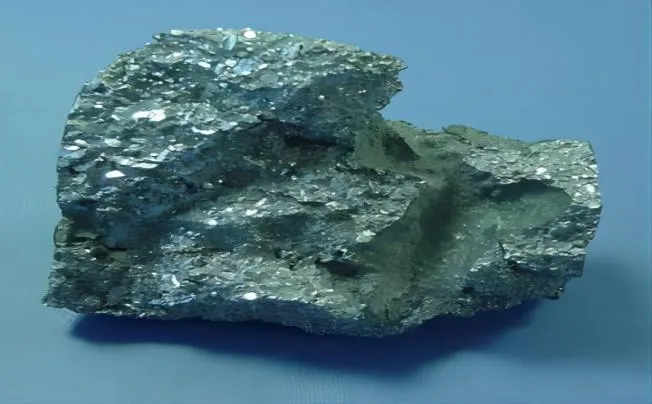

What is Ferrotungsten 80?

An electric furnace is used to reduce tungsten-containing ores, such as wolframite, to carbon to create ferrotungsten 80. It is made up of around 20% iron (Fe) and 80% tungsten (W). It is widely employed in many different industries because of its special qualities. For instance, it is mostly added as an additive when making alloy steel that contains tungsten, like high-speed steel. Ferrotungsten 80 comes in various grades, each with a unique composition and impurity limit.

What Are The Properties of Ferro Tungsten 80?

Elevated Density

Ferro Tungsten 80 is a hefty alloy because tungsten has a very high density. With a density of about 15.6 g/cm2, it is among the densest materials yet discovered.

Elevated Melting Point

Due in part to tungsten’s extraordinarily high melting point of 3422°C (6192°F), Ferro Tungsten 80 is resistant to high temperatures.

Durability and Resistance to Wear

Tungsten is renowned for having extraordinary wear resistance and toughness. Similar characteristics make Ferro Tungsten 80 appropriate for uses requiring resistance to abrasion, distortion, and wear.

Superior Tensile Potency

Because of its high tensile strength, Ferro Tungsten 80 is appropriate for uses where durability and strength are needed.

Excellent electrical and thermal conductivity

Ferro Tungsten 80 exhibits good thermal and electrical conductivity in comparison to many other materials, but not as high as pure tungsten.

Resistance to Corrosion

Because Ferro Tungsten 80 resists corrosion well, it can be used in hard situations or in settings where specific chemicals are present.

What is Ferro Tungsten 80 Used For?

1. Aerospace and Defence: Ferro Tungsten 80 finds employment in these fields in applications such as radiation shielding, high-density alloys for balance weights, armor-piercing projectiles, and parts that need to be extremely strong and resistant to wear.

2. Automotive: Ferro Tungsten 80 is utilized in parts that need to be extremely hard and dense, including crankshaft weights and ballast weights.

3. Mining and Drilling: Ferro Tungsten 80’s great strength and wear resistance make it a valuable material for mining and drilling tools.

4. Electronics: Ferro Tungsten 80 finds application in high-voltage connections, electrodes for electrical discharge machining (EDM), and heating components.

5. Filament Manufacturing: Ferro Tungsten 80’s high melting point and superior electrical conductivity are employed in the manufacture of filament for electronic tubes and incandescent lamps.

What Standards Do Qualified Ferrotungsten Need To Follow?

W content: 70%~85%

Packing: In iron drums of 100kgs net each or in plastics of 1000kgs net each

Particle Size: 5-100mm

Remarks: Any special requirements to the products can be discussed.

The particular guidelines that qualified ferrotungsten must adhere to may change based on the sector and application.

Ferrotungsten manufacturing, use, and quality control may be subject to various industry and regional rules and standards. Aspects including composition, purity, production procedures, environmental effects, and safety may be covered by these standards.

It is advised to speak with regulatory agencies, industry-specific groups, or pertinent standards organizations such as national standards organizations, ASTM International, or ISO (International Organisation for Standardisation) to find out the precise requirements for qualified ferrotungsten.

These groups frequently create and uphold standards that guarantee the compliance, safety, and quality of products used in a range of sectors. Manufacturers and consumers of ferrotungsten can make sure that their products fulfil industry norms and the necessary requirements by consulting the relevant standards.