What is Ferro Vanadium?

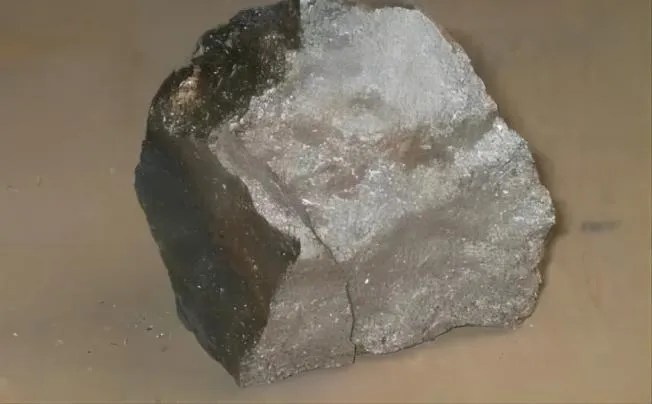

One significant alloy product containing vanadium is ferro vanadium. In steel metallurgy operations, it is frequently utilized as a furnace ingredient. In an electric arc furnace, vanadium pentoxide (V2O5) is combined with aluminium or ferrosilicon (FeSi75) to produce ferro vanadium. Depending on the technique of manufacturing, the final ferro vanadium alloy has a vanadium concentration ranging from 35 to 85 percent.

What is Ferro Vanadium 60?

A particular kind of ferrovanadium alloy known as ferrovanadium 60 has a vanadium content of roughly 60%. Ferrovanadium 60 is frequently used in the fabrication of tool steel, carbon steel for infrastructure, and high-strength steel as an alloying and strengthening agent. It can strengthen crude steel’s tensile strength, increase its resistance to wear, and make it lighter. It can also be added to a range of steels, including as tool and high-strength low-alloy (HSLA) steels, to strengthen, hardness, and prevent corrosion.

Vanadium pentoxide (V2O5) is reduced in an electric arc furnace using ferrosilicon (FeSi75) or aluminium to produce ferrovanadium 60. V2O5 is reduced to vanadium metal by the reduction process, which subsequently reacts with iron to create a ferrovanadium alloy. The resulting ferrovanadium 60 alloy has roughly 60% vanadium by concentration.

What Are the Grades of Ferrovanadium 60?

Ferrovanadium is available in grades with vanadium contents of 40%, 60%, and 80%. The proportion of vanadium in the alloy is indicated by these grades. Ferrovanadium contains trace amounts of silicon, aluminium, carbon, sulphur, phosphorus, arsenic, copper, manganese, and vanadium in addition to iron. The alloy’s impurities can account for up to 11% of its weight and identify the ferrovanadium grade. With 80% vanadium, FeV80 is the most often used grade. Steel, including carbon steel, alloy steel, high-strength steel, and HSLA (High Strength Low Alloy) steel, is frequently produced using ferrovanadium.

What is Ferro Vanadium 60 Used For?

Ferrosilicon (FeSi75) or aluminium are reduced with vanadium pentoxide (V2O5) in an electric arc furnace to produce ferrovanadium 60. Vanadium metal is created during the reduction process from V2O5, and it combines with iron to create a ferrovanadium alloy. About 60% of the vanadium in the resultant ferrovanadium 60 alloy is present.

For silicon reduction, a mixture of ferrosilicon, lime, slag, and vanadium pentoxide is heated to 1850°C in an electric arc furnace. Vanadium in V2O5 is reduced to metallic vanadium by the silicon in ferrosilicon. The metallic vanadium then combines with iron to produce ferrovanadium. Excess lime and V2O5 are then added to consume the silicon and purify the metal. Between 35 and 60 percent vanadium is produced during the process.

As an alternative, aluminium reduction entails combining aluminium, lime, V2O5, and iron in an electric arc furnace. Vanadium in V2O5 is reduced by aluminium to metallic vanadium, a process akin to that of silicon reduction. Ferrovanadium alloy is created when vanadium metal dissolves into iron. Between 70 and 85 percent of the vanadium in the resultant ferrovanadium is present.

To summarise, ferrosilicon or aluminium is reduced with vanadium pentoxide in an electric arc furnace to produce ferrovanadium 60. The concentration of vanadium in the final ferrovanadium alloy is determined by the particular reduction procedure.

What is the Difference Between Ferrovanadium 60 and Ferrovanadium 40?

The vanadium content of ferrovanadium 60 and ferrovanadium 40 is the primary distinction between them. Vanadium is present in 60% of ferrovanadium 60 and 40% of ferrovanadium 40. The characteristics of the alloy and its appropriateness for various applications are determined by the amount of vanadium present.

When making steel, ferrovanadium is frequently added to improve the material’s hardness, strength, and corrosion resistance. The required steel characteristics and the user’s requirements determine the precise amount of vanadium in the alloy.

It is significant to remember that ferrovanadium contains trace amounts of silicon, aluminium, carbon, sulphur, phosphorus, arsenic, copper, and manganese in addition to vanadium and iron. The ferrovanadium grade is determined by the different concentrations of these impurities.