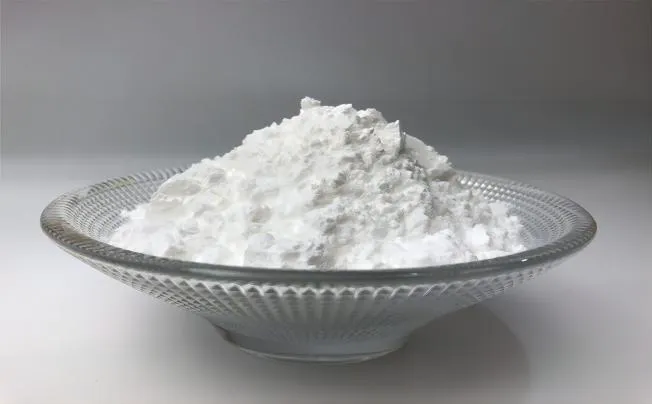

What is Ferromolybdenum Powder?

Ferromolybdenum powder is a metal alloy of iron and molybdenum with a high molybdenum content, usually between 60% and 75%. Iron, aluminium, and molybdenum (VI) oxide (MoO3) are heated to create it. Molybdenum is produced in situ when the oxide and aluminium join through an aluminothermic process.

The main application of ferromolybdenum powder is as an alloying agent in the manufacturing of high-strength low-alloy (HSLA) steel. Before casting, it is added to molten steel to enhance its qualities, including hot workability, hardenability, creep resistance, and neutron absorption. Ferromolybdenum is added to steel to increase its strength and toughness, which makes it appropriate for a variety of applications in the aerospace, construction, and automotive industries.

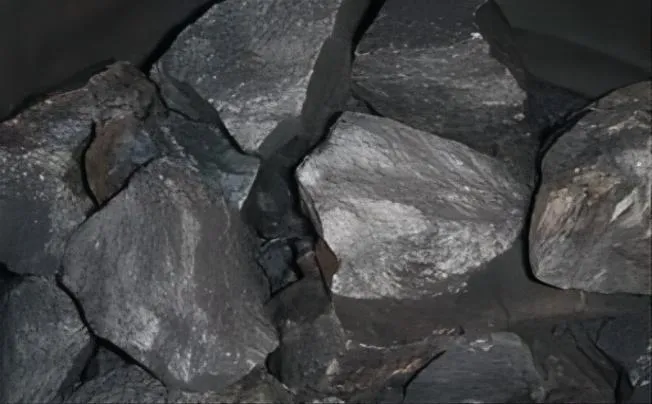

Molybdenum is mined and converted into molybdenum (VI) oxide (MoO3) in order to make ferromolybdenum. After that, the oxide is combined with aluminium and iron oxide to undergo an aluminothermic reduction. Usually, the finished alloy is delivered in the form of tiny briquettes or fine powder, enclosed in steel drums or bags.

Properties of Ferromolybdenum Powder

Powdered ferromolybdenum has a number of qualities that make it useful for a range of uses. The following are ferromolybdenum powder’s salient features:

1. Apparent density: Ferromolybdenum powder has an apparent density of around 9 g/cm³ or 0.3251 lb/in³.

2. Melting point: The melting point range of ferro molybdenum powder is 3029–3119 °F, or 1665-1715°C.

3. Alloying agent: The main application for ferromolybdenum powder is in the alloying of high-strength low-alloy (HSLA) steel. It enhances the steel’s capacity to withstand heat, harden, resist creep, and absorb neutrons.

4. Purification: To guarantee its purity and uniformity, ferromolybdenum powder might go through purification procedures such as electron beam melting.

5. Form: Small briquettes or fine powder, packed in bags or steel drums, are the usual forms of ferromolybdenum powder supply.

Applications: Due to its capacity to increase the strength and toughness of steel, ferromolybdenum powder finds application in a number of industries, such as aerospace, automotive, and construction.

What is Ferromolybdenum Powder Used For?

The main application of ferromolybdenum powder is as an alloying agent in the manufacturing of high-strength low-alloy (HSLA) steel. Before casting, it is added to molten steel to enhance a number of the steel’s characteristics, such as hot workability, hardenability, creep resistance, and neutron absorption.

Ferromolybdenum is added to steel to increase its strength and toughness, which makes it appropriate for a variety of applications in the aerospace, construction, and automotive industries.

It is important to remember that ferromolybdenum is created via a particular manufacturing method and is not found in nature. Heating a mixture of iron, aluminium, and molybdenum(VI) oxide (MoO3) causes an aluminothermic reaction that produces molybdenum in situ.

Ferromolybdenum powder, the finished product, is normally delivered in bags or steel drums as fine powder or tiny briquettes.

How is Ferro Molybdenum Powder Produced?

Powdered ferromolybdenum is made using a particular manufacturing procedure.

Source materials: Iron, aluminium, and molybdenum(VI) oxide (MoO3) are combined to produce ferromolybdenum powder.

An aluminothermic reaction is produced when heat is applied to the mixture of MoO3, aluminium, and iron. Molybdenum is created in situ as a result of the combination of the oxide and aluminium in this reaction.

Purification (optional): Methods such as electron beam melting can be used to further purify the ferromolybdenum that is produced. The final product’s uniformity and quality are enhanced by this purifying process.

Application in the manufacturing of steel: High-strength low-alloy (HSLA) steel is frequently produced using ferromolybdenum as an alloying agent. Before casting, it is added to molten steel to improve its qualities, including creep resistance, hot workability, hardenability, and neutron absorption.

Suppliers: Companies all over the world produce ferromolybdenum. Several noteworthy providers are the European companies Derek Raphael and Co Ltd and MTALX LTD, as well as the American company Langeloth Metallurgical Company.