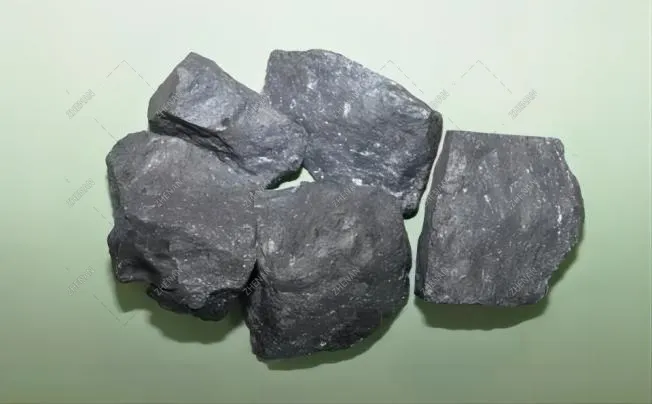

What are the Physical Properties of Ferrotungsten 70?

The primary constituents of ferrotungsten 70 are iron (Fe) and tungsten (W), with tungsten making up roughly 70% of the alloy. Because of its special qualities, this alloy is frequently employed in a variety of applications. These are Ferrotungsten 70’s salient characteristics:

Density: At 15.5 grammes per cubic centimetre (g/cm3), ferrotungsten 70 generally has a high density. Because of its high density, it can be used in situations where compactness and weight are crucial considerations.

Hardness: 70 Ferrotungsten is a very hard substance. As one of the hardest elements, tungsten can be utilized in applications where wear resistance is required, and its presence serves to boost its hardness.

High Melting Point: At roughly 3,410 degrees Celsius (6,170 degrees Fahrenheit), tungsten has a very high melting point. Ferrotungsten 70’s alloy has a high melting point due to the tungsten in it, which makes it appropriate for high-temperature applications.

Ferrotungsten 70 can be magnetised since it is ferromagnetic. Because of this characteristic, it can be used in applications that call for magnetism, like electromagnetic and magnetic storage systems.

Corrosion resistance: 70 ferrotungsten is excellent for corrosive situations and has good corrosion resistance, especially when compared to pure iron.

Thermal expansion: The coefficient of thermal expansion of 70 ferrotungsten is comparatively low. This indicates that compared to other materials, it expands and contracts less with temperature variations. Applications needing dimensional stability over a broad temperature range can benefit from this characteristic.

What is Ferrotungsten 70 Used For?

1. Steel production: To improve the steel’s qualities, ferrotungsten 70 is added during the steel-making process. It enhances steel’s hardness, strength, and resistance to wear, making it appropriate for uses requiring high-performance steel, such as construction materials, tools, and machinery parts.

2. Electrical and electronic components: Ferrotungsten 70 is beneficial in the manufacturing of electrical and electronic components due to its magnetic characteristics. Transformers, inductors, magnetic storage devices, and other electromagnetic applications all employ it.

3. Aerospace and Defence: The aerospace and defense sectors use ferrotungsten 70. Because of its great density and hardness, it can be used in missiles and aircraft as counterweights, armor-piercing projectiles, and ballast weights.

4. Mining and drilling equipment: Ferrotungsten 70 is useful in the production of mining and drilling equipment because of its hardness and wear resistance. It is a component of cutting tools, drill bits, and weather-resistant, hard-wearing parts.

5. Coatings that resist corrosion: Ferrotungsten 70 is a coating material that may be applied to a variety of surfaces to provide them with corrosion resistance. It is used as a shield for parts like pipelines, valves, and chemical processing machinery that are subjected to corrosive conditions.

6. High-temperature applications: Ferrotungsten 70 is appropriate for high-temperature applications because of its high melting point and thermal stability. It is utilized in heating elements, furnace parts, and other high-temperature operating components.

What are the production steps of Ferrotungsten 70?

- Preparing the raw materials, mostly iron and tungsten, is the first step in the production process. Ores and other sources are possible sources for these minerals.

- Weighing and mixing: To create Ferrotungsten 70 with the correct composition, the iron and tungsten components are weighed and combined in the appropriate ratios. A uniform dispersion of the components is guaranteed by the mixing procedure.

- Melting: The mixed raw materials are then subjected to a high-temperature melting process. This process involves heating the materials in a furnace or other suitable equipment until they reach their respective melting points. The high melting point of tungsten (around 3,410 degrees Celsius) requires a furnace capable of reaching and maintaining such temperatures.

- Ferrotungsten 70 is formed by a metallurgical reaction of melted raw materials; the composition of the molten mixture is carefully regulated to ensure that the desired result is obtained. The molten Ferrotungsten 70 is then cast into a desired shape or solidified into bars, ingots, or other forms for use or further processing.