Related Titanium Powder Elements

With an atomic weight of 47.867, titanium (atomic symbol: Ti, atomic number: 22) is a Period 4 Group D element. Each titanium shell contains [2, 8, 10, 2] electrons in the [Ar]3d24s2 electron configuration. The van der Waals radius is 187 pm, and the titanium atom in the Bohr model has a radius of 147 pm. William Gregor discovered titanium in 1791, and Jöns Jakob Berzelius isolated the metal for the first time in 1825.

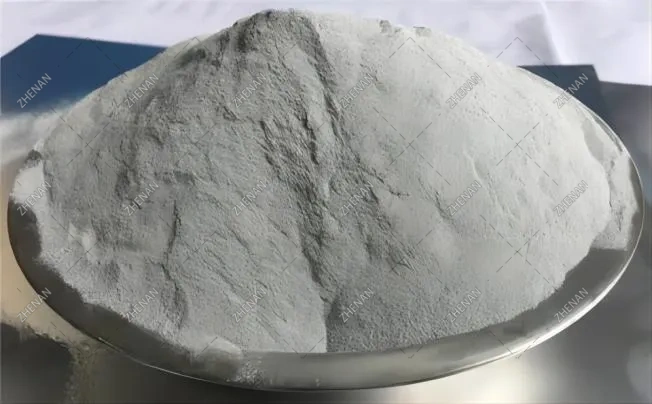

Titanium has a metallic look that is silvery grey-white. Its physical and chemical characteristics resemble those of zirconium. Both are in the same group in the periodic table of elements and have an equal amount of valence electrons. Titanium element There are five naturally occurring isotopes of titanium: 46Ti, 50Ti, and 48Ti, which are the most common (73.8%).

Advantages of Titanium powder

Of all the known metals, titanium has the best strength-to-weight ratio. Because of this, it is perfect for a wide range of industrial applications, and its use is expanding. Because of its exceptional strength and resistance to corrosion, it is highly appreciated. Titanium powders can be used to make lightweight aircraft parts as well as high-performing automotive components. Titanium-based powders are appropriate for customised dental and medical implants due to their high biocompatibility.

Titanium powders are well-suited for use in additive manufacturing because of their near-net shape capabilities, which allow for little to no material loss and the elimination of the requirement for conventional machining to achieve the desired final component form.

What are the Classifications of Titanium Powder?

Titanium Alloy powder

Titanium alloy powder refers to a powdered form of titanium that is mixed with other elements to create alloys with specific properties. Titanium alloys are created by combining titanium with elements such as aluminium, vanadium, or nickel, among others. These alloys are known for their high strength, low density, and excellent corrosion resistance. Titanium alloy powder is used in various industries, including aerospace, automotive, medical, and additive manufacturing. It is commonly used in the production of lightweight and high-strength components for aircraft, spacecraft, and automobiles. In the medical field, titanium alloy powder is used to create implants and prosthetics due to its biocompatibility and ability to integrate with human bones.

Titanium Dioxide Powder

TiO2, or titanium dioxide powder, is a white, odourless powder that finds widespread use in a variety of industries and applications. It is a naturally occurring titanium oxide with some qualities that make it useful in various industries.

Titanium dioxide is a common white pigment found in paints, coatings, polymers, and inks. It gives these products outstanding brightness, opacity, and whiteness.

Sunscreen: Because titanium dioxide can both reflect and disperse ultraviolet light, it is a common ingredient in sunscreens and other skincare products. It creates a barrier of protection on the skin, functioning as a physical sunscreen.

Food addition: Candy, chewing gum, and baked goods are just a few of the foods that employ titanium dioxide (E171) as a food addition. It is employed to provide these items opacity and a white colour.

Titanium dioxide is employed as a catalyst in some chemical processes, including those that result in the generation of hydrogen gas and the breakdown of contaminants in wastewater.

Titanium dioxide powder can function as a photocatalyst when it comes into contact with UV light. Applications for it include water treatment, air purification, and self-cleaning surfaces.

Cosmetics: Colour, opacity, and UV protection are all provided by titanium dioxide, which is present in foundations, powders, and lipsticks.

What is Titanium Powder Used For?

1. Additive Manufacturing: Commonly referred to as 3D printing, additive manufacturing makes extensive use of titanium powder. With less waste and more design flexibility, it enables the manufacturing of intricate and customised parts.

2. The aerospace and automotive industries employ titanium powder to make lightweight, very durable parts for cars, spaceships, and aeroplanes. It provides exceptional corrosion resistance and strength-to-weight ratio.

3. Medical Field: Because titanium powder is biocompatible and can fuse with human bone, it is employed in the manufacture of prosthetics and medical implants. It is frequently utilised in surgical instruments, dental implants, and orthopaedic implants.

4. Coatings and Pigments: Paints, coatings, plastics, and inks all employ titanium powder as a pigment. It gives these products outstanding brightness, opacity, and whiteness.

5. Catalysts: Hydrogen gas production and the breakdown of contaminants in wastewater are two examples of chemical reactions in which titanium powder is employed as a catalyst.

6. Sunscreen and Cosmetics: Because titanium dioxide can reflect and disperse UV rays, it is generated from titanium powder and found in sunscreens and cosmetics. In addition to offering UV protection, it aids in getting the right colour and opacity in cosmetics.